Design

ZAQQ Barefoot shoes are the closest thing to not wearing shoes at all! Our aim is to incorporate our innovative designs into the unique properties of ZAQQ Barefoot Shoes and we use soft leather to enable the luxury of freedom of movement for your feet to help them cope with the strains of modern life.

The exposed seam on the inside of the shoe serves as a stylish contrast to the smooth leather side and we pay the same attention to detail to the inner sole as to the outside. We use hunting leather to ensure each ZAQQ Barefoot shoe has a unique appearance. We play skillfully with both sides of the leather to guarantee not only a comfortable fit but also an attractive design.

Construction

Your feet are a wonder of nature and have evolved to the perfect design over millions of years. Muscles, bones, joints and tendons form a complex flexible and sensitive system.

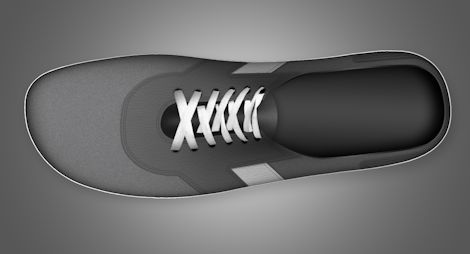

Your new ZAQQ shoes were designed for the well-being of those feet. The front of the shoe allows plenty of space for your toes to move and a completely flat sole with no heel keeps your ankles flexible. A lightweight cushioned sole protects your joints and guarantees comfort.

Check out your new ZAQQ Barefoot Shoes - do you see how accurate the seams are? Inside the shoe you see the seam which connects the bottom to the upper. This seam is deliberately visible so you can admire the technical perfection of the traditional art of shoemaking. We have ensured the shoes lace smoothly and comfortably to offer optimal support yet without the metal eyelets which would spoil the appearance of your shoe. A cap in the heel provides stability and yet prevents blisters.

Our premium hunting leather is 2mm thick and therefore we do not need a lining resulting in a smooth, breathable and flexible shoe.

We use the same material for the inner sole rather than a fabric or plastic inlay to guarantee the breathability your feet need, banishing sweat forever!

As you can see, we have incorporated many ideas and innovations to give you a special footwear experience. Our latest Barefoot shoes are the lightest range ever and weighing less than 200 grams you'll hardly feel your new ZAQQ Barefoot shoes.

Leather cutting

In our factory we tailor leather by hand to the required size. Of course, modern laser cutting tables or water cutting machines are faster and more efficient but we prefer the human eye and decades of experience working with leather.

We use a stencil of the required part and mark the leather with a pencil, cutting out with a special knife so as to prevent any damage to the surface.

Each piece of leather has two different degrees of tension directions. This means, depending on the direction in which the leather is cut, there are areas of the shoe that stretch more than others. Your ZAQQ Barefoot shoes should have more stretch across the width than the length however they should not be so flexible that they fail to retain their shape. Your shoes will continue to fit your foot perfectly for many years to come.

It is truly an art to cut the leather perfectly to the correct size and shape but hand cutting allows us to individually develop each ZAQQ Barefoot shoe to perfection.

Shoelast

It is a common misconception that everyone's feet are the same. Women's feet differ from men's feet in numerous respects. A woman's foot is for example differently proportioned with a narrower heel and wider forefoot than a male foot. You can easily measure this at home to check. If one were to simply shrink a man's shoe and sell as a lady's shoe then it would be slightly too wide in the heel and narrow in the forefoot to be comfortable. To build really comfortable shoes, you therefore need different shapes.

A shoelast is a shaped piece of wood or plastic and is required for the production of a shoe, because it forms the shape of the foot. A shoe model is then ultimately developed using this form. The shoe model is the heart and soul of each shoe as if it is not conscientiously developed and adapted to the foot then the finished shoe can never be made easily and accurately.

Almost all manufacturers use a combi-shoelast which is a uniform frame for both men and women, because this is obviously much easier to produce and saves a lot of development time and money. However the results are shoes that really fit neither a man nor a woman. This results in a shoe that allows the material to pinch the foot until they have been worn in sufficiently to mould to the correct shape.

We believe that advice such as "use a Band-Aid until the shoes are worn in" or "make the shoe wet to help it to conform to the correct shape" is a sign that the manufacturer has substandard quality. We therefore took a lot of time and have developed three different frames, one for men, one for women and one for children. The advantage for you is that your new ZAQQ Barefoot Shoes do not require to be broken in and you can be sure of complete comfort from the moment you take them out of the box and put them on for the very first time.

If you would like to visit us in our factory south of Berlin, we would be delighted to explain the difference between our methods and those of other manufacturers and we would happily show you the bars that we use for manufacturing different shoes. Transparency ensures quality and we live by this principle on a daily basis.

Sewing

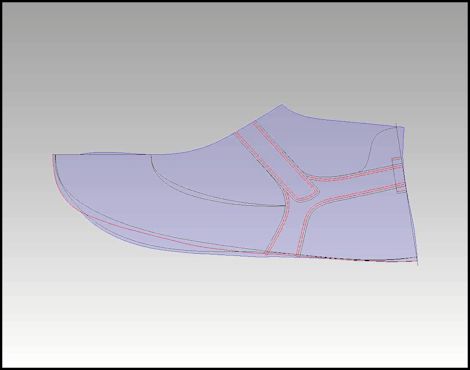

Once they have been cut from the leather, the different parts of the shoe need to be connected in sequence with each other.

Anyone who has ever tried to sew something knows that this work takes great effort. To sew the seam correctly requires careful planning and selection of appropriate materials.

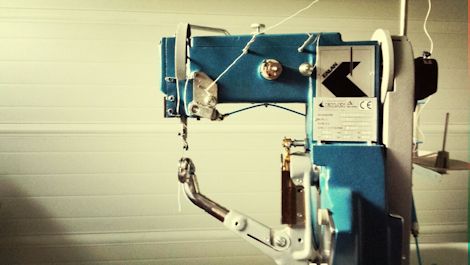

In order to produce the perfect seam you need to select the right needle, the appropriate thread, the best sewing method and of course the right machine. Not only must the correct needle and thread be chosen but also the actual style of seam needs to be selected carefully. Depending on whether it is a zig zag stitch, a linking seam or double seam we have a specialised sewing machine for each type of seam in our factory because when you have perfect working conditions you can produce exceptional products.

Strobel

The "Strobel" is a method for sewing a flexible shoe that is ideal for our ZAQQ Barefoot shoes. The advantage of the "Strobel" method is that it produces neither ridges, uneven areas or hard edges and the volume of the liner can be utilised to the maximum.

You feel this flexible comfort with every step that you take in your new ZAQQ Barefoot shoes. In fact, you could twist, turn, squash or compress your ZAQQ Barefoot shoes and you can be sure that they will suffer no damage at all.

Check out your new ZAQQ Barefoot shoes closely. Inside you can clearly see the sewn seam that connects the lower part of your shoe with the upper shaft. Notice how evenly and accurately this seam is sewn and in this you can admire the true craftsmanship of our employees. Why should we hide something so beautiful and of such high quality under an insole? If a shoe literally "fits like a glove", then often this is due to its Strobel style.

The word "Strobel" originates from the company that invented shoes for this special sewing machine, the "Strobel" machine. However, you'll find a Strobel machine does not compare with a normal sewing machine, because its method of operation is fundamentally different. >7p>

A Strobel machine connects the two parts of a shoe in a very extraordinary way. A needle pierces the thread through both pieces of leather then a small hook takes up the thread and guides it over the leather back to the front edge where the needle captures the thread and again pierces through the leather. Thus strap is lined up to loop until the end of the shoe has been completely enclosed.

The Strobel sewing technique guarantees a shoe that is really accurate and technical skill and experience is absolutely necessary to connect the smooth sole of the shoe to the much larger upper shell.

Quality Seal

Every piece of footwear that leaves our Barefoot shoe factory in south of Berlin bears the ZAQQ seal of quality and the vital stamp saying "Made in Germany".

Even to produce this stamp we rely on an exceptional solution. For high quality workmanship and an exclusive look these logos are embossed permanently into the leather in a complex process using a heat stamp.

As the name implies here a stamp made of brass is heated to a temperature of exactly 180° Celsius and then pressed using a press in the piece of leather. Applying just the right amount of pressure for exactly the right period of time results in the stamp being perfectly embossed into the leather guaranteeing that it will maintain its shape and appearance for a long time.

The advantage of this over transfer templates or simple colour templates is that the seal can not be gradually removed by mechanical action. A shoe that was created with a ZAQQ logo maintains this seal of quality approval throughout its whole lifespan.

As you can see, your new ZAQQ Barefoot shoes are really well thought out down to the last detail and are a unique piece of design.

Sole bonding and stiching

One of the last and yet most difficult steps is the stitching of the sole. Again we use sophisticated machines to achieve the best and most professional results.

We have spent a very long time trying different methods in order to find the most sustainable and high-quality product as the sewing of the sole is individual and demanding work.

The leather must be carefully prepared and for this purpose, each shaft is masked with tape by hand and then the leather is carefully rubbed. The complete sole is roughened at the adhesion surface to undergo an optimum connection with the adhesive. Following this process, the sole is carefully pulled by hand to the shaft and placed in the sole press. An air filled rubber cushion one one side and a ball and heel molded piece on the other then press together under high pressure resulting in the rubber cushion completely wrapping around the sole and enabling them to stick together tightly and precisely. The right balance is crucial. If too much adhesive is applied it would be pushed out to the edges however with too little glue the sole will not fit correctly and will not stick. If the pressure of the press is set too high, then the shaft or the sole can be damaged.

So therefore you can see that gluing a sole sounds easier than it really is. This is also the reason why we have spared no expense or effort because the only way we can guarantee that every shoe is made with the same dedication and passion with which we have developed is to produce them using our own special methods in our own dedicated factory.

After gluing, ZAQQ shoes are actually sewn. An old proverb says that a seam can be replaced by nothing but an even stronger seam. Of course, modern adhesives are able to connect a sole to an upper however there is always the possibility that the adhesive will wear away over time and cause the shoes to fall apart.

For this reason, we border-stitch the sole to maintain our high quality standards and the exclusivity of your new ZAQQ Barefoot shoes. Many manufacturers know this and therefore mimic a seam on their shoes to create an appearance of higher quality. We love quality here at ZAQQ but are never satisfied with half measures.